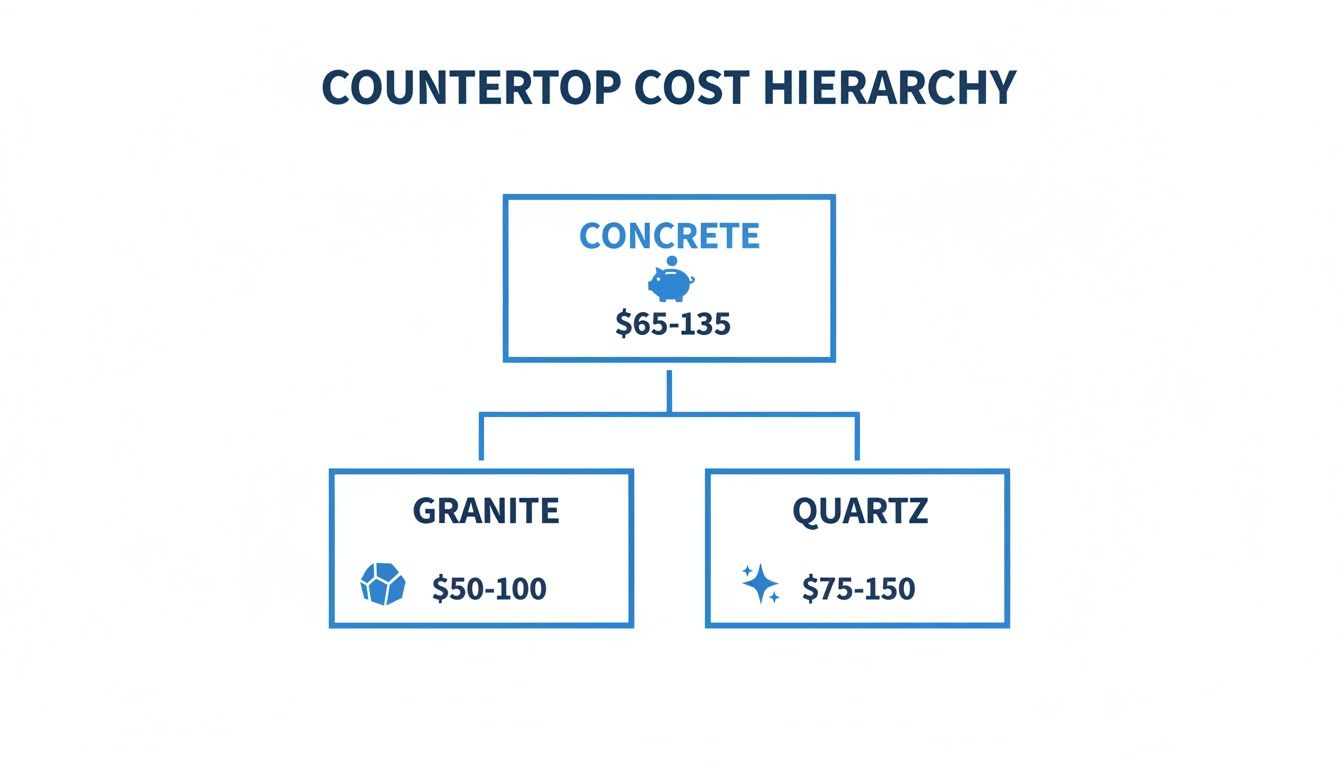

When you start pricing out concrete countertops, you'll find they typically land somewhere between $65 and $135 per square foot for a professional job. This puts them right in the ring with high-quality granite and quartz, making them a solid mid-to-high-end option. The final number on your invoice will really come down to the details—how much custom work you want, the complexity of the design, and the artisan's skill level.

Your Quick Guide to Concrete Countertop Costs

Let's clear one thing up right away: concrete countertops aren't the budget, DIY-friendly material you might imagine. In the world of high-end kitchen design, professionally crafted concrete is a premium surface. People choose it for the incredible level of customization and the one-of-a-kind look it brings to a space.

Think of it less like pouring a sidewalk and more like commissioning a piece of functional art for your home. The price reflects that artistry, covering not just raw materials but the intricate fabrication process and the specialized skills needed for a flawless installation. In fact, labor alone can make up 40–60% of the total cost, especially if your design includes complex shapes or sinks built right into the countertop. What you're paying for is a surface that is literally made for your space, something you just can't get from a standard slab of stone.

Quick Cost Comparison: Concrete vs Other Countertops

To give you a better sense of where concrete fits into the market, let's stack it up against some other popular countertop materials. This quick comparison will help you see how it aligns with your overall budget.

| Material | Average Installed Cost per Sq. Ft. | Best For |

|---|---|---|

| Concrete | $65 – $135 | Homeowners wanting complete customization in color, shape, and finish. |

| Granite | $50 – $100 | Those who appreciate unique, natural stone patterns and excellent durability. |

| Quartz | $75 – $150 | Buyers seeking a non-porous, low-maintenance surface with consistent color. |

| Laminate | $20 – $50 | Budget-focused projects requiring a wide variety of colors and patterns. |

As you can see, concrete holds its own among the top-tier choices. Its rising popularity is part of a much bigger story in the global countertops market, which hit a value of around $148 billion in 2024 and is still growing.

To put it in local terms, installing concrete countertops in a standard 40-square-foot kitchen in a Boca Raton condo could run anywhere from $2,600 to $5,400. It's a significant investment, but one that pays off in pure custom style. You can always dig deeper into the global countertops industry to understand the trends driving these prices.

Now, let's break down the specific factors that can push that price tag up or down.

What Really Drives Your Concrete Countertop Price?

That initial price per square foot you see? Think of it as a starting point. The real cost of your concrete countertops comes down to the details—the series of choices that transform a basic slab into a piece of functional art tailored for your kitchen or bathroom.

It's a lot like ordering a custom suit. The fabric gives you a base price, but the final cost depends on the cut, the lining, the type of buttons, and the hand-stitching. With concrete, a simple rectangular slab is the off-the-rack version; adding things like a waterfall edge or an integrated sink is what makes it bespoke.

Thickness and Reinforcement

Most concrete countertops you'll see are a solid 1.5 inches thick. It's the sweet spot for durability without being excessively heavy. But if you’re chasing that bold, chunky industrial look, you might go for 2 inches or more. Just know that a thicker slab uses more material and adds serious weight. You might even need to reinforce your cabinets to support it, which is an added cost to factor in. Getting the material estimate right is key here, which is why accurately calculating concrete volume for the job is so important.

Custom Shapes and Complex Edges

This is where the artisan's skill—and the labor costs—really starts to show. Pouring a simple, straight-edged island is one thing. Creating one with dramatic curves, custom cutouts, or multiple levels is a whole different ballgame.

The edge profile you choose has a huge impact on the final price, too:

- Square or Eased Edges: These are the standard for a reason. They deliver a clean, modern look with minimal fuss, making them the most budget-friendly choice.

- Bullnose or Beveled Edges: If you want a softer, rounded, or angled look, it takes more intricate forming and finishing work, which will bump up the price a bit.

- Waterfall Edges: This is the showstopper. The countertop surface appears to flow seamlessly down the side of the cabinet or island all the way to the floor. It’s a high-impact look that requires incredibly complex formwork, resulting in a significantly higher cost.

Before we even get into finishes, it helps to see where concrete sits among its competitors.

As you can see, concrete’s base cost is right in the mix with granite and quartz. But its final price is almost entirely driven by the custom touches we’re talking about.

Integrated Features and Finishes

Building features directly into the countertop is where you get that seamless, one-of-a-kind feel. An integral sink—where the sink basin is molded from the same piece of concrete as the counter—is a popular upgrade. It looks fantastic, but the complex mold required means it can easily add $1,000 or more to the total cost.

The same goes for color and texture. Adding pigments to the concrete mix for a custom hue or hand-troweling the surface for a unique finish requires more time and a higher level of skill from your fabricator. Grinding the surface to expose the aggregates (the small stones and sand inside) is another beautiful but labor-intensive option.

This level of customization is precisely why concrete is such a big deal in the decorative concrete market, an industry valued at $19.35 billion in 2024. People want something unique, and they’re willing to invest in it. To figure out if these custom elements are right for you, check out our complete guide on the pros and cons of concrete countertops. It’ll help you decide where to spend your money for the biggest impact.

Choosing Between Concrete Granite and Quartz

When you're knee-deep in a remodel, picking a countertop can feel like a massive decision. You're usually staring down three heavy hitters: concrete, granite, and quartz. They all hang out in a similar premium price range, but looking past the initial sticker price is crucial for making a choice you'll be happy with for years to come. It’s less about which one is "best" and more about which one is the perfect fit for your kitchen, your lifestyle, and your design vision.

It's a bit like choosing a vehicle. A rugged pickup truck, a sleek luxury sedan, and a high-performance sports car might have similar price tags, but you're buying them for completely different reasons. The same logic applies here. Granite delivers raw, natural beauty, where every single slab is a unique piece of geological art. Quartz, on the other hand, offers engineered perfection—a non-porous, practically zero-maintenance surface with predictable patterns.

Concrete? That’s the sculptor’s clay of the countertop world. Its real value isn't trying to mimic stone; it's in its almost limitless potential for customization.

Aesthetics and Customization

This is where concrete really separates itself from the rest of the pack. While you can certainly find a stunning slab of granite or quartz, you’re ultimately choosing from what the quarry or factory has already produced. With concrete, your imagination is pretty much the only limitation.

- Shape and Form: Want a countertop that cascades down the side of your island in a waterfall edge? Or maybe one with an integrated sink and drainboard? How about a top that curves gracefully around a unique architectural column? Concrete makes this happen in a way that a slab of stone just can't.

- Color Freedom: You’re not just flipping through a catalog of swatches. Pigments can be mixed right into the concrete to create virtually any color imaginable, from subtle, earthy grays to bold, vibrant blues that become the kitchen's undeniable focal point.

- Unique Inlays: This is where things get really personal. You can embed all sorts of things directly into the surface—recycled glass for a terrazzo look, smooth river stones, or even metal shavings for an industrial-chic finish. It's a chance to create something truly one-of-a-kind.

Quartz brings color consistency to the table, which is a huge plus for many homeowners who want a uniform look. You can dive deeper into its specific perks and pricing in our detailed guide on the cost of quartz countertops. Granite’s allure is in its wild, untamed veining and patterning—no two pieces will ever be identical.

Durability and Maintenance

All three of these materials are tough, but they each have their own quirks. Granite and concrete are both naturally heat-resistant, so you can set a hot pan down in a pinch without panicking (though using trivets is always best practice). Quartz, which is an engineered stone bound with resins, is a bit less tolerant of direct, high heat.

Maintenance is another huge deciding factor.

Concrete is naturally porous, so its long-term durability and stain resistance really come down to the quality of the sealer. A top-notch sealer makes it tough against stains and a breeze to clean, but it will need to be reapplied every few years. It's a small trade-off for getting a completely custom surface.

If "low maintenance" is your mantra, quartz is the undisputed champion. Its non-porous surface means it never needs sealing. Granite, much like concrete, is also porous and needs to be sealed periodically to keep oils and liquids from seeping in and causing stains.

Feature Showdown Concrete vs Quartz vs Granite

To make this decision a bit easier, let's put these materials head-to-head in a simple comparison. This table breaks down the key differences at a glance, helping you match the material to what matters most to you.

| Feature | Concrete | Quartz | Granite |

|---|---|---|---|

| Customization | Extremely High | Moderate | Low |

| Heat Resistance | Excellent | Good | Excellent |

| Stain Resistance | Good (with sealer) | Excellent | Good (with sealer) |

| Maintenance | Periodic resealing | None | Periodic resealing |

| Best For | Unique shapes & colors | Consistency & low upkeep | Natural, one-of-a-kind patterns |

At the end of the day, choosing concrete isn't just picking a countertop—it's an intentional design statement. You're opting for a handcrafted, perfectly imperfect surface that brings a unique architectural and personal touch to your home that neither a manufactured nor a quarried material can quite replicate.

What Goes Into the Installation Process and Timeline

One thing to understand right away is that concrete countertops aren't like granite or quartz, which are cut from a massive slab. Instead, they are custom-made, functional pieces of art crafted specifically for your kitchen. The process is a true display of craftsmanship that unfolds over several weeks, which is a big part of what you're paying for.

It all starts with a detailed design consultation. This is where we map out every single dimension, cutout for your sink and cooktop, and any other special features you've dreamed up. From there, your fabricator creates an exact template of your cabinets. This template is the blueprint that guarantees a perfect fit, whether the countertops are made in a workshop (pre-cast) or poured right in your kitchen (cast-in-place).

From a Liquid Mix to a Solid Surface

With the blueprint ready, it's time for the pour. A custom blend of concrete, pigments, and reinforcements gets carefully worked into the molds. This is where the artisan’s touch makes all the difference, as they hand-trowel the surface to get the exact texture and finish you want.

After the pour comes the most crucial and time-intensive stage: curing. This isn’t just about letting it dry. Curing is a chemical reaction where the concrete slowly hardens and develops its final, impressive strength.

Curing is a waiting game. It typically takes a full 28 days for the concrete to reach its maximum structural integrity. If you rush this part, you risk a weaker countertop that's more likely to crack down the road. This long curing period is a major factor in the labor cost because it ties up space in the workshop and requires careful monitoring.

This patient, meticulous process is what ensures your countertop will be tough enough to handle daily life for decades, making it a worthwhile investment. To see how this fits into the grand scheme of things, it helps to look at a typical kitchen renovation timeline.

The Finishing Touches and Final Install

Once the slab has fully cured, the real transformation begins. Artisans get to work grinding, sanding, and polishing the surface to bring out its unique character and achieve the sheen you've chosen—anything from a soft, earthy matte to a slick, high-gloss look. This is also when we apply multiple coats of a high-performance sealer, which is essential for protecting against stains and moisture.

Finally, installation day arrives. A professional crew carefully transports the heavy slabs into your home, expertly setting them onto the cabinets. They make sure every seam is tight and every connection is flawless. If the countertops were cast-in-place, this stage involves managing dust and keeping the area well-ventilated. The entire journey, from that first template to the final sealed surface, is a multi-week commitment to skill and patience. That's what you're truly investing in.

Smart Ways to Budget for Your Countertop Project

Getting the custom concrete countertop you've been dreaming of doesn't have to mean blowing your budget. The trick isn't about cutting corners; it's about making smart choices that get you the look you want without paying for features you don't need.

Think of it this way: you're in control of the final price tag. The key is to know where the real costs are hidden—in the labor-intensive details—and then decide which of those custom touches give you the most bang for your buck.

Simplify Your Design Elements

If you're looking for the single biggest way to manage the cost of your project, this is it: simplify the design. The more complex the shape, the more elaborate the edge, and the more built-in features you add, the more hours your fabricator has to spend. And time is money.

Here are a few practical ways to get that high-end look while keeping costs in check:

- Stick to Standard Thickness: There’s a good reason 1.5-inch thick countertops are the industry standard. They're incredibly durable and have a nice, substantial feel, but they aren't so heavy that you need to reinforce your cabinets. This saves you on both materials and potential carpentry costs.

- Choose a Simple Edge Profile: A clean, square edge is timeless and the most budget-friendly option. Fancy profiles like a bullnose or waterfall edge look great, but they require much more complicated form-building and finishing work, which drives up the labor bill.

- Rethink the Sink: An integral sink—where the sink is seamlessly part of the countertop—is a showstopper, but it can easily add $1,000 or more to the total. You can save a significant amount by choosing a classic undermount or even a drop-in sink, and the final look is still fantastic.

A critical step in managing your budget is to request a detailed, itemized quote from your contractor. This document should clearly separate the costs for materials, fabrication labor, and installation, empowering you to see exactly where your money is going and identify potential areas for savings.

Remember, your countertops are just one piece of the puzzle. When planning a full kitchen remodel, it's wise to see how everything fits together financially. For a wider view on budgeting for the whole space, this a guide to kitchen renovation costs and savings can be a huge help.

By making deliberate decisions on these key design points, you can get that beautiful, artisan-crafted concrete countertop and still keep the project comfortably within your budget. No sticker shock, just a stunning new kitchen.

Your Top Questions About Concrete Countertop Costs, Answered

Even with all the numbers laid out, you've probably still got a few questions. That's a good thing. Choosing a countertop is a huge decision for your home, and digging into the details of what concrete countertops cost is the best way to feel great about your choice.

Let's dive into the questions we hear most often from homeowners right here in Boca Raton and Delray Beach. I'll give you clear, no-nonsense answers to help you get a handle on the final details.

Are Concrete Countertops Cheaper Than Granite?

This is probably the biggest myth we have to bust. People hear "concrete" and think of sidewalks, but that's not what we're talking about here. While the raw material itself isn't expensive, you're not paying for a bag of Sakrete; you're paying for true craftsmanship. The real cost is in the meticulous, hands-on labor—building custom forms, mixing the perfect blend, pouring, curing, and applying a flawless finish.

A professionally crafted concrete countertop will typically run you somewhere between $65 and $135 per square foot. That puts it right in the same ballpark as many mid-to-high-end granite slabs, which often fall in the $50 to $100 per square foot range. In fact, if you're looking for unique colors or a complex design, a custom concrete top can easily cost more than a standard piece of granite.

Do Concrete Countertops Crack Easily?

It's a fair question. All concrete can develop tiny, hairline cracks as it cures and settles over time, but this has become a much smaller issue thanks to modern techniques. The pros aren't just pouring standard concrete; they use highly specialized mixes fortified with things like glass fibers or polymer resins. These additives give the countertop incredible tensile strength and a bit of flexibility.

Here's a good way to think about it: The concrete in your driveway is built for one thing—bearing immense weight. The mix for your countertop is a different beast entirely. It's engineered to handle the daily grind of a kitchen, from hot pans to the occasional dropped glass, making significant cracking extremely rare.

A solid installation and a quality sealer are the other half of the equation. When it's all done right, your countertops will be incredibly tough. Any faint, non-structural fissures that might show up years down the road are usually seen as adding to the material's unique, living character.

How Do I Maintain Concrete Countertops?

Good news—it's easier than you think. Day-to-day cleaning is simple: just a soft cloth with a little mild soap and water will do the trick. The big rule is to steer clear of harsh chemicals, abrasive scrubbers, or anything acidic like vinegar or lemon juice. Those can eat away at the sealer that protects the surface.

The most important piece of maintenance is resealing. Depending on the sealer your fabricator used and how much action your kitchen sees, you’ll want to have them resealed every 1 to 3 years. It’s a pretty quick process that keeps your countertops protected from stains and moisture, ensuring they stay beautiful for the long haul.

How Long Do Concrete Countertops Last?

With a professional installation and basic care, your concrete countertops can genuinely last a lifetime. They are incredibly durable and stand up well to heat and scratches. One of their best features is that, unlike many other materials, they can often be repaired. A pro can usually fix small chips or deep scratches by filling, sanding, and resealing the spot, making it look new again. This kind of longevity makes them a fantastic long-term investment in your home.

Ready to explore a one-of-a-kind concrete countertop for your home? The team at Kitchen Renovations Perfected offers complimentary design consultations to help you bring your vision to life in Boca Raton, Delray Beach, and Parkland. Schedule your free consultation today!