Let's get right to it—you want to know what you'll actually spend on quartz countertops. The honest answer is that it really depends, but a solid ballpark figure for most projects is anywhere from $50 to $150 per square foot, fully installed.

That price isn't just for the slab itself. It bundles together the material, the custom cutting and shaping (what we call fabrication), and the final installation by a pro. Knowing this range gives you a realistic starting point for your budget.

Your Guide to Quartz Countertop Costs

When you're planning a kitchen remodel, the first question is always the same: "What's this going to cost me?" For countertops, especially a top-tier choice like quartz, understanding the numbers is the key to making a smart decision you'll be happy with for years.

This guide is designed to give you that clarity. We'll break down the final price tag into its core components so you can see exactly what you're paying for.

Think of your final quote as a recipe with three main ingredients:

- The Quartz Slab: This is your raw material. The price here is all about the brand, how intricate the design is, and the rarity of the color. A simple, solid white will cost less than a slab that perfectly mimics Calacatta marble with dramatic veining.

- Fabrication Work: This is where the artistry comes in. A skilled fabricator takes that raw slab and turns it into your countertop. They cut it to the exact dimensions of your cabinets, create the edge profile you chose, and make precise cutouts for your sink, faucet, and cooktop.

- Professional Installation: This is the make-or-break final step. Experienced installers make sure your new counters are perfectly level, that any seams are practically invisible, and that everything is securely in place to last a lifetime.

By looking at the costs this way, you can easily understand your estimate. It’s no longer one big, scary number—it’s a set of clear, manageable costs that you have control over.

Quartz is definitely a premium material. That $50 to $150 per square foot price point places it comfortably above options like laminate (which runs closer to $10-$30/sq ft) or entry-level granite. You can check out more countertop market insights to see how different materials stack up.

With this foundation, you're ready to build a realistic budget and bring your dream kitchen to life without any financial surprises.

Deconstructing the Price: What Drives Quartz Costs?

Ever walk through a stone yard and wonder why one gorgeous quartz slab costs so much more than another? They might look similar at a glance, but the price difference comes down to a blend of artistry, engineering, and good old-fashioned brand reputation. Getting a handle on these factors is the key to making a smart investment in your kitchen.

I like to compare it to buying a car. A simple, solid-colored slab is your reliable, base-model sedan. It's tough, looks great, and does its job beautifully. But a slab with dramatic, multi-layered veining that mimics a rare cut of Calacatta marble? That's the luxury sports car with a custom paint job. Both are fantastic choices, but the complex design and precision manufacturing of the high-end option naturally command a higher price.

Let's pull back the curtain and see exactly what you're paying for when you choose your quartz.

The Impact of Quality Tiers and Design

Here's the first thing to know: not all quartz is created equal. The industry generally groups it into tiers based on how complex the design is and the quality of the raw materials. This is probably the biggest single factor affecting your cost per square foot.

-

Builder-Grade or Standard Tier: This is your entry point. Think simple, solid colors or fine, uniform speckles. These slabs are workhorses—perfect if you want a clean, minimalist look or need something ultra-durable for a high-traffic rental property without breaking the bank.

-

Mid-Grade Tier: Now we're getting into more visual flair. In this range, you'll find slabs with subtle veining, more dynamic patterns, and a wider color palette. It’s a fantastic middle-ground, offering a great balance of eye-catching design and value.

-

Premium or Designer Tier: This is the top of the line, where the artistry really shines. These slabs feature breathtakingly realistic marble-like veining, unique color blends, and sometimes a translucent quality that gives them incredible depth. The manufacturing for these is far more involved, often requiring multiple layers of pigments and patterns to get that "natural" one-of-a-kind look.

The difference isn't just skin deep, either. Premium slabs often have a higher concentration of pure quartz crystals and use more advanced polymer resins, which can boost clarity and overall durability.

Brand Recognition and Manufacturing Process

Just like with your fridge or dishwasher, the brand name on a quartz slab really does matter. Companies like Caesarstone, Silestone, and Cambria have spent decades pouring money into research, development, and stringent quality control. That reputation for excellence costs more, but it brings some real-world benefits.

A well-known brand often means you’re getting a more rigorous manufacturing process, better color consistency from one slab to the next, and a much more robust warranty. That peace of mind is a big part of what you’re investing in.

For a deeper dive into how quartz stacks up against another popular choice, check out our detailed quartz versus granite countertops comparison. It’s a huge help when you’re weighing the long-term value and maintenance of each.

The manufacturing process itself is also a massive cost driver. Think about it: creating a slab with deep, random veining that flows organically is a much more complex and time-consuming process than just mixing up a batch of speckled material. The precision engineering needed to make sure a premium slab is strong and uniform throughout is a huge part of its final ticket price.

Why Slab Thickness Matters

Finally, let's talk about a detail that seems small but has a real impact on your budget: slab thickness. Quartz countertops typically come in two standard thicknesses: 2 centimeters (about 3/4 inch) and 3 centimeters (about 1 1/4 inch).

Now, a 3cm slab has 50% more material than a 2cm slab, but the price increase is usually only around 10-20%. Why? Because most of the fabrication and installation costs—cutting, polishing, and hauling—are the same no matter how thick the stone is.

So, why spring for the thicker option?

- Durability and Presence: A 3cm slab just feels more substantial. It gives you a high-end, solid look and offers superior strength, which is especially important for large islands or countertops with long, unsupported overhangs.

- Edge Profiles: If you want a more decorative edge, like an Ogee or Dupont profile, a thicker slab is the way to go. You can carve these directly into the stone instead of having to laminate the edge (gluing a second strip underneath to fake the thickness).

- No Sub-Top Needed: A 3cm counter can usually be installed directly onto your cabinets. A 2cm counter, on the other hand, almost always needs a plywood sub-top for support, which adds a little extra to the labor bill.

Ultimately, your choices in these three areas—tier, brand, and thickness—are what will shape the final quote. Understanding where your money goes is crucial. Most engineered stone countertop cost analyses show that the raw material makes up about 40% of the total project price, with labor and fabrication eating up the rest.

What Goes Into Fabrication and Installation Fees?

The price you see for a quartz slab is just the starting point. The real work—and a major part of your budget—is turning that raw, heavy piece of stone into a countertop that fits your kitchen perfectly. This is the world of fabrication and installation, and getting a handle on these costs is key to understanding your total investment.

Think of it like buying a beautiful bolt of fabric for a custom suit. The material has its price, but the real value comes from the master tailor who measures, cuts, and stitches it to fit you flawlessly. Your countertop fabricator is that tailor, transforming raw material into a functional piece of art for your home.

Beyond the stone itself, a huge chunk of your project's cost comes from these professional services. To get a better feel for how these charges add up, it can be helpful to read about understanding installation costs for home improvements.

Breaking Down Fabrication Charges

Fabrication is where all the custom details you picked out become a reality. Each choice adds a layer of complexity and hands-on labor, which will show up in your final quote. You can expect these services to make up 20% to 30% of your total project cost.

Here’s a look at what you’re really paying for:

-

Edging: This is the finished profile along the edge of your countertops. A simple, slightly rounded “eased” edge is usually standard and included in the base price. But if you want something more decorative like an Ogee, Dupont, or a full Bullnose, it requires special tools and more time, which adds to the cost.

-

Cutouts: Every single opening for a sink, cooktop, or faucet has to be cut with absolute precision and then polished. Undermount sinks, which are incredibly popular, demand more polishing work around the interior of the cutout compared to drop-in models, making them a bit more expensive.

-

Seams: Unless you have a very small, straight-run kitchen, you'll likely need to join two or more pieces of quartz. Creating a tight, level, and nearly invisible seam is a true craft that requires a ton of skill. The labor for this critical step is a major part of the fabrication fee.

A "waterfall" edge, where the countertop material cascades vertically down the side of an island, is one of the biggest fabrication upcharges you can get. It's not just that it uses more material; it also requires incredibly meticulous cuts and seaming to make sure the veins line up perfectly for that seamless, flowing look.

The Cost of Professional Installation

Once your slab is cut, edged, and polished to perfection, it has to be carefully brought to your home and professionally installed. Installation isn't just about dropping the stone into place. It’s a detailed process that ensures your countertops will last for decades and look amazing. This part of the job typically accounts for about 30% of your total quote.

Key installation steps include:

- Templating: Before a single cut is made, a professional will create a precise template of your cabinets. This is a crucial step that guarantees a perfect fit, even if your walls aren't perfectly straight.

- Labor and Logistics: A slab of quartz can weigh hundreds of pounds. Getting it from the truck to your kitchen without damaging it (or your home) requires a skilled crew and specialized equipment.

- Tear-Out and Disposal: If you have old countertops, the installation team will need to remove and haul them away. This is almost always a separate line item on your invoice.

The Boca Raton Factor in Labor Costs

If you're a homeowner in Boca Raton or other South Florida communities, it’s important to know that our local market directly impacts labor costs. Rates for skilled tradespeople here are often higher than the national average, thanks to high demand and a higher overall cost of living.

This means the fabrication and installation part of your quote might be a bit steeper than what you'd see quoted in other parts of the country. A hot real estate market and a constant flow of high-end renovation projects keep the best installers very busy, and their pricing reflects that. The only way to get a true picture is to get a detailed, itemized quote from a local fabricator who can break down these regional costs for you.

Real-World Quartz Countertop Project Costs

It's one thing to talk about price per square foot, but what does that actually look like for a real kitchen? Let’s move past the abstract numbers and look at how these costs come together in common kitchen scenarios.

By walking through three different project sizes—from a compact galley to a sprawling luxury space—you’ll get a much clearer picture of how a budget takes shape. We'll break down the expenses for the quartz slab itself, the custom fabrication work, and the final installation, so you can see exactly where your money goes.

Small Galley Kitchen (30 sq. ft.)

First up, let's consider a compact but common kitchen layout, perfect for a condo or smaller home. At 30 square feet, a galley kitchen usually means a simple, straight run of countertops. This keeps the fabrication pretty straightforward.

For this example, we’ll use a mid-grade quartz—a popular choice that delivers beautiful designs without the premium price tag. The homeowner is keeping it simple with a standard eased edge and one cutout for an undermount sink.

Here’s how the costs stack up:

- Quartz Slab (Mid-Grade at $65/sq. ft.): $1,950

- Fabrication (Eased Edge & Sink Cutout): $600

- Old Countertop Removal & Disposal: $250

- Installation Labor: $900

- Estimated Total Cost: $3,700

As you can see, the material makes up just over half the total cost. The hands-on work—fabrication and installation—accounts for a significant chunk of the budget, which is important to remember.

Standard Suburban Kitchen (50 sq. ft.)

Now, let's scale up to a more typical suburban kitchen. With 50 square feet of counter space, we're likely looking at an L-shaped layout, maybe even a small island. This introduces a bit more complexity. More surface area obviously means more material, but it also means more cuts, more finished edges, and probably a seam.

We'll stick with a mid-grade quartz slab but upgrade the edge profile to a more decorative beveled style, which adds a little to the fabrication fee. This kitchen also needs two cutouts: one for the sink and one for a cooktop.

- Quartz Slab (Mid-Grade at $65/sq. ft.): $3,250

- Fabrication (Beveled Edge, 2 Cutouts, 1 Seam): $1,200

- Old Countertop Removal & Disposal: $400

- Installation Labor: $1,500

- Estimated Total Cost: $6,350

Notice how the fabrication costs jump as the kitchen gets bigger and more complex. Every extra cutout and the need for a professionally finished seam adds to the final bill. It really shows how your design details influence the bottom line.

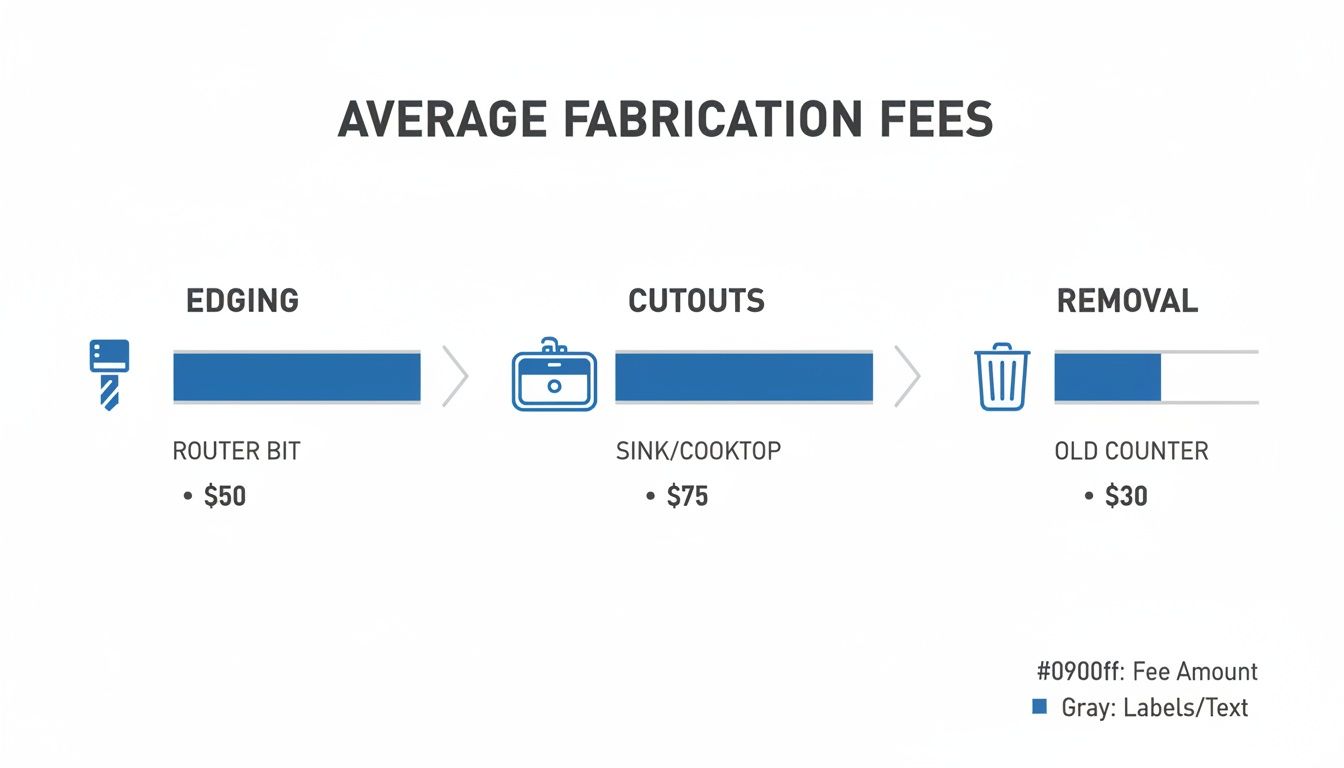

This infographic breaks down some of the most common fabrication charges you'll see on a quote.

It’s a great reminder that seemingly small choices, like your edge profile or sink style, are distinct services with their own price tags.

Large Luxury Kitchen With an Island (75 sq. ft.)

Finally, let’s go big with a large, high-end kitchen. A project with 75 square feet of quartz will almost certainly feature a massive island, a perimeter with multiple turns, and other premium touches. The scale and complexity here demand a lot more material and significantly more skilled labor.

In this scenario, the homeowner chose a top-tier designer quartz with dramatic veining. They also opted for a decorative Ogee edge and a waterfall edge on the island, plus three cutouts for a main sink, a smaller prep sink, and a cooktop.

A waterfall edge is a major cost driver. This is where the countertop slab appears to flow vertically down the sides of an island or cabinet run. It requires extra material and incredibly precise craftsmanship to align the veining for a seamless, continuous look, which boosts both material and labor costs.

Here’s the breakdown for this luxury project:

- Quartz Slab (Premium at $90/sq. ft.): $6,750

- Fabrication (Ogee Edge, 3 Cutouts, Waterfall Edge): $2,800

- Old Countertop Removal & Disposal: $600

- Installation Labor: $2,250

- Estimated Total Cost: $12,400

Looking at the overall investment for a full remodel helps put your countertop budget in perspective. To learn more about managing the entire project, check out these resources on accurate kitchen renovation costs.

Ultimately, these examples show that while square footage is a primary cost factor, your design choices are just as critical in shaping the final price tag for your new quartz countertops.

Sample Quartz Countertop Project Cost Breakdown

This table provides a side-by-side comparison of the three project examples, making it easy to see how costs scale with the size and complexity of the kitchen.

| Cost Item | Small Kitchen (30 sq. ft.) | Average Kitchen (50 sq. ft.) | Large Kitchen (75 sq. ft.) |

|---|---|---|---|

| Material (Quartz Slab) | $1,950 | $3,250 | $6,750 |

| Fabrication & Customization | $600 | $1,200 | $2,800 |

| Old Countertop Removal | $250 | $400 | $600 |

| Installation Labor | $900 | $1,500 | $2,250 |

| Estimated Total Project Cost | $3,700 | $6,350 | $12,400 |

From these figures, it's clear that your total investment grows exponentially as you add more square footage and custom features like premium edges or waterfall details.

Budgeting Smartly to Save on Your Countertops

Getting that gorgeous, high-end quartz look doesn't have to mean draining your savings account. I've seen countless homeowners get the kitchen of their dreams on a realistic budget, and it all comes down to a bit of strategic planning. With a few savvy choices, you can dramatically lower the final bill without sacrificing an ounce of style.

It’s all about knowing where you can be flexible. From the specific slab you pick to the way your layout is planned, every little decision can nudge your bottom line in the right direction.

Tap Into Your Fabricator's Remnant Inventory

Here’s one of the best-kept secrets in the business: remnant inventory. When a fabricator cuts up massive slabs for a big kitchen project, there are almost always smaller, unused pieces left over. These "remnants" are perfect for smaller jobs, and the best part is they're sold at a serious discount.

This is a fantastic strategy for projects like:

- Bathroom vanities: You can often find a stunning, designer-quality piece in the remnant pile that’s the perfect size for a standard vanity.

- Small kitchen islands: If your island is compact and doesn't need a full slab, a remnant could be your golden ticket to savings.

- Laundry room counters or wet bars: These utility spaces are ideal candidates for scoring a high-quality material without the premium price tag.

Make Smart Choices on Thickness and Edges

Another major way to control costs is to get practical about the specs of your countertop. A thicker slab can feel incredibly substantial, but it isn't always essential for the durability or the look you want, especially in certain areas.

For example, a 2cm thickness (about ¾ of an inch) is more than durable enough for most kitchens and bathrooms. While the 3cm slab is often seen as the luxury standard, simply opting for 2cm can shave a solid 10-20% off your material cost. Don't worry about support—2cm slabs are installed over a simple plywood sub-top, which is an inexpensive and standard part of the process.

The same logic applies to your edge profile. A simple, clean eased edge is almost always included in the base price. But if you start looking at fancier profiles like an Ogee or Dupont edge, you're adding labor and specialized tool work, which will bump up your fabrication costs.

Thinking about the long game is just as important as the upfront price. Because quartz is non-porous, it never needs to be sealed. That alone will save you hundreds of dollars and a lot of hassle over the years compared to materials like granite that demand regular maintenance.

Consider Color and Brand Popularity

Finally, don't forget how much simple supply and demand can affect pricing. Just like with anything else, certain quartz colors and patterns become trendy, and that popularity drives the price up. You can often find a more competitive price by choosing a popular, widely available color from a well-known brand.

It's those really exotic, marble-look designs with intricate veining that always command a premium because they're more complex to manufacture. If you want a full breakdown of your options, our guide on how to choose kitchen countertops is a great place to start.

This demand isn't just local; it's a global trend. The worldwide market for quartz kitchen countertops hit an impressive USD 6.83 billion in 2024, which just shows how many people are investing in these beautiful, low-maintenance surfaces. You can dig into the numbers and see what's driving the market in this detailed industry analysis. By making these kinds of informed choices, you can get a high-end result that fits comfortably within your budget.

From Quote to Finish: Your Countertop Installation Journey

Getting from a price quote to a gleaming new quartz countertop isn't a one-day affair. It’s a process, a series of steps that ensures the final product is a perfect fit for your home. Let’s walk through what you can expect so you feel in control every step of the way.

Think of it less like buying an off-the-shelf product and more like having a custom suit made. Every phase is designed to get the details just right, minimizing mistakes and guaranteeing that seamless, professional look you’re after.

Step 1: Getting Solid, Comparable Quotes

Your first move is to gather quotes, but the trick is to make them apples-to-apples. The more detailed you are, the more accurate the price will be. A simple sketch of your kitchen layout with some basic measurements is a great place to start.

To get quotes you can actually compare, give every fabricator the same list of specs:

- Your Quartz Choice: If you have a specific brand and color in mind, name it.

- Edge Style: Are you thinking of a simple, standard eased edge or something more decorative? Let them know.

- Sink Type: Specify whether you'll be using an undermount or a drop-in sink.

- Tear-Out: Be clear about whether you need them to handle the removal and disposal of your old countertops.

Step 2: The All-Important Templating Appointment

After you've picked your fabricator, they'll schedule a time to come out and "template." Honestly, this is the most critical part of the entire installation. A technician will visit your home to create a precise digital or physical pattern of your cabinets.

This isn't just about length and width. The template captures every little imperfection—walls that aren't perfectly straight, subtle dips in cabinets, and the exact placement for your sink and stove. It’s the master blueprint that ensures a glove-like fit. Just remember, your cabinets have to be fully installed and secured in their final position before this happens.

Pro Tip: Make sure your new sink, faucet, and cooktop are physically on-site for the templating appointment. The technician needs them to confirm the exact cutout dimensions and positions before a single cut is made in your beautiful new slab.

Step 3: Fabrication and Installation Day

Once the template is finalized, it heads back to the shop where the real magic happens. Your chosen quartz slab is cut to the blueprint's exact specifications using specialized saws. The team will also polish the edges and create the cutouts for your sink and appliances. This whole fabrication process usually takes one to two weeks.

Finally, it’s installation day! The crew will bring the finished pieces to your home, carefully set them in place, and level them perfectly. If your countertop has seams, they’ll join them with a specialized, color-matched epoxy that makes them nearly invisible. After they mount the sink and clean up, you get to step back and admire your new kitchen centerpiece.

To see how this process fits into the bigger picture, check out our guide to the complete kitchen renovation timeline.

Common Questions About Quartz Countertop Costs

As you get closer to making a decision, a few final questions always seem to pop up. That's perfectly normal. Getting straight answers is the best way to feel confident about your investment, so let's tackle the questions we hear most often from homeowners.

Is Quartz More Expensive Than Granite?

This is the classic countertop debate, and the truth is, it depends. While you might find some entry-level granite slabs for a lower price, the cost for rare and exotic granite can easily surpass even high-end quartz.

- Quartz: You'll typically find it priced between $50 to $150 per square foot, installed. The pricing is usually much more consistent.

- Granite: The range is wider, often from $40 to over $200 per square foot, installed. That price swings wildly based on how rare the stone is and where it came from.

While their initial costs can overlap, quartz often pulls ahead in long-term value. Because it’s non-porous, it never needs sealing. Granite, on the other hand, needs to be resealed every year or two to keep it from staining. That’s a recurring maintenance cost—and a chore—that quartz owners get to skip entirely.

Does the Brand of Quartz Affect the Price?

It absolutely does. Think of it like buying a car or a major appliance; the brand name often says a lot about the quality, warranty, and the company's reputation. Big names like Caesarstone, Silestone, or Cambria put a ton of money into research, development, and making sure every slab meets their high standards.

So, you're paying for more than just a logo. You're investing in better color consistency from one slab to the next, more advanced manufacturing that creates incredibly realistic veining, and a solid warranty that stands behind your purchase. A lesser-known brand might save you some cash upfront, but a premium brand delivers a whole lot of peace of mind.

How Can I Get the Most Accurate Project Quote?

To get a number you can actually count on, you need to give your fabricator good information. Vague details will only get you a vague price. Before you even pick up the phone, pull together a few key things to make sure your quote is spot-on.

An accurate quote is built on specifics. The more detailed your request, the fewer surprises you'll have on the final invoice. It empowers both you and your fabricator to be on the same page from day one.

When you reach out to a potential fabricator, have these details ready:

- A Simple Layout Sketch: Nothing fancy, just a drawing with the basic measurements of your countertop space.

- Material Choice: If you’ve already picked out a quartz brand and color, let them know.

- Edge Profile: Mention if you’re thinking of a standard eased edge or something more decorative.

- Sink and Cooktop Info: Note if your sink is an undermount or drop-in and have the specs for your appliances handy.

- Tear-Out Needs: Be clear about whether they need to rip out and haul away your old countertops.

Ready to transform your kitchen with a surface that’s as durable as it is beautiful? The team at Kitchen Renovations Perfected is here to guide you through every step, from selecting the perfect quartz to flawless installation.