So, you’re thinking about concrete countertops? The first question on everyone’s mind is always about the price. Let’s get right to it. On average, you can expect the concrete kitchen countertops cost to land somewhere between $70 to $150 per square foot, fully installed.

For a pretty standard 35-square-foot kitchen, that puts your total project investment in the ballpark of $2,450 to $5,250. This price point places concrete firmly in the premium category, right alongside high-end natural stone and quartz.

Your Quick Guide To Concrete Countertop Pricing

When you hear “concrete,” it’s easy to picture a sidewalk, but that’s not what we’re talking about here. In the world of kitchen design, concrete is a completely bespoke, artisanal material.

Think of it this way: a slab of granite is cut from a mountain, but a concrete countertop is created from scratch, just for you. This hand-crafted nature is exactly why its cost is comparable to other luxury materials. You’re not just buying a product; you’re commissioning a piece of functional art from a skilled craftsperson.

Concrete Countertop Cost At A Glance

To give you a clearer picture for your budget, here’s a simple breakdown of what to expect. This table provides a quick summary of the numbers before we dive into the factors that influence them.

| Cost Metric | Typical Price Range |

|---|---|

| Price Per Square Foot (Installed) | $70 – $150 |

| Average Project (35 sq. ft.) | $2,450 – $5,250 |

| Key Cost Components | Labor, Material Mix, Finish, Thickness |

These figures give you a solid starting point. As you plan, it’s helpful to see how this one choice fits into the bigger picture of your project, which often includes the 7 elements of a dreamy kitchen renovation.

How Concrete Stacks Up Against Other Materials

It’s crucial to understand where concrete fits in the countertop market. It’s not a budget-friendly alternative to laminate; it’s a premium surface for homeowners who want something truly unique and personalized.

Concrete’s real value is in its endless potential for customization. While granite has whatever pattern nature gave it and quartz offers engineered consistency, concrete is a blank slate. You get to decide the exact color, shape, thickness, and texture—a level of control no other material can offer.

Here’s a quick comparison to put it all in perspective:

- Laminate ($20-$50/sq. ft.): The go-to for tight budgets, but it can’t match the durability or custom look of other options.

- Granite ($60-$100/sq. ft.): A durable, popular choice with unique natural veining, but you’re limited to the colors and patterns found in nature.

- Concrete ($70-$150/sq. ft.): Incredibly durable and completely customizable. Your imagination is the only limit.

- Quartz ($80-$150/sq. ft.): A tough, non-porous engineered stone that offers consistent, predictable patterns.

- Marble ($100-$200/sq. ft.): Absolutely stunning and timeless, but it’s a softer stone that requires diligent care and maintenance.

At the end of the day, choosing concrete is an investment in a one-of-a-kind surface that will truly define your kitchen’s style.

What Really Drives Your Concrete Countertop Cost

When you start pricing out concrete countertops, you’ll quickly realize it’s not a simple per-square-foot calculation. Think of it more like commissioning a piece of art; every detail you choose, from the basic form to the final finish, plays a role in the final price tag.

The same goes for your concrete kitchen countertops cost. Your design choices are what truly shape the budget. Let’s break down the key factors that influence your total investment, so you know exactly where your money is going.

Precast vs. Poured-In-Place Installation

The very first decision is a big one: will your countertops be made in a workshop or built right in your kitchen? This choice sets the stage for everything that follows, impacting logistics, labor, and, of course, price.

- Precast Concrete Countertops: These are the most common for a reason. They’re crafted off-site in a controlled workshop environment, where artisans can perfect the mix, color, and cure. This gives you an incredibly consistent and predictable result. The finished slabs are then carefully transported and installed. You can typically expect precast to run $70 to $110 per square foot.

- Poured-In-Place Countertops: For this method, the countertop is literally built in your home. We construct forms right on your cabinets, then mix and pour the concrete on-site. It’s the perfect solution for creating massive, seamless islands or unique shapes that would be impossible to move. Because of the intensive on-site labor and dealing with your home’s environment, this option is a bigger investment, usually landing between $90 and $150 per square foot.

For most people, precast hits the sweet spot of quality and value. But if your heart is set on a truly seamless, one-of-a-kind design, poured-in-place offers unbeatable creative freedom.

Thickness and Reinforcement

That solid, substantial feel is a huge part of concrete’s appeal. The standard thickness for a countertop is 1.5 to 2 inches. This range provides a great balance of visual heft and structural integrity without asking too much of your cabinets.

If you want a thicker, more dramatic look, you can absolutely go beyond 2 inches, but keep in mind this adds material cost and significant weight. You might even need to have your cabinetry reinforced. On the flip side, super-thin profiles are possible with modern mixes like Glass Fiber Reinforced Concrete (GFRC), but these require specialized techniques that can also affect the final price.

Edge Profiles and Intricate Shapes

Just like with granite or marble, the edge style gives your countertop its final personality. A simple, clean edge is the most straightforward and budget-friendly, while more decorative profiles require more time and skill to create.

Here’s a quick look at how different edge styles can impact the cost:

| Edge Style | Description | Cost Impact |

|---|---|---|

| Square | Clean, minimalist lines perfect for modern kitchens. | Low |

| Beveled | A subtle angled edge that softens the look. | Moderate |

| Bullnose | A fully rounded, classic edge style. | Moderate |

| Ogee | An intricate, S-shaped curve for a luxurious feel. | High |

| Waterfall | The countertop extends vertically down the sides of an island. | High |

It’s not just the edges, either. Any complex shape, from graceful curves to cutouts for undermount sinks or integrated drainboards, requires more complex formwork and finishing labor, which will be reflected in the cost.

The beauty of concrete is its fluidity—it can be molded into virtually any shape. However, this flexibility means that every custom curve, integrated sink, or unique feature adds to the craftsmanship and time required, which is reflected in the final quote.

Finishes, Stains, and Sealers

The finishing stage is where the magic really happens, turning a simple slab into a stunning surface. A basic, lightly sanded finish with a standard matte sealer is your most economical option.

But the customization possibilities are nearly endless. A high-gloss, polished surface, for example, is a multi-step, labor-intensive process. It involves grinding the concrete with progressively finer diamond pads to achieve that mirror-like sheen, which adds significantly to the cost.

Other finishing touches to consider:

- Coloring: Mixing pigments directly into the concrete (integral color) gives you a consistent, through-body color and is generally more cost-effective. Topical acid stains create more variegated, stone-like patterns but require more artistry and time.

- Sealers: A quality acrylic sealer is a good baseline. Upgrading to a high-performance, food-safe epoxy or urethane coating will cost more upfront but gives you superior protection against stains and scratches down the road.

Each of these choices adds another layer to the final calculation, letting you fine-tune the balance between your vision and your budget.

Understanding Labor: The Art and Science of Installation

When you get a quote for a concrete countertop, the biggest number on the page usually isn’t the material—it’s the labor. This is often the single biggest factor driving the concrete kitchen countertops cost, and for very good reason. Installing these countertops is far more of an art form than simple construction; it’s a specialized craft that demands a unique set of skills.

Unlike a sheet of laminate or even a pre-cut slab of granite that just needs to be set in place, a concrete countertop is created from scratch, custom-made for your specific kitchen. This isn’t just about pouring some cement into a wooden box. It’s a true artisan’s process, one that transforms a raw, utilitarian material into a luxurious centerpiece for your Boca Raton home.

Why Skilled Craftsmanship Is Non-Negotiable

Making a concrete countertop is a multi-stage performance where every single step has to be perfect. It all starts with building hyper-accurate molds, or “forms,” that dictate the final shape, thickness, and edge profile of your new surface. Even the tiniest error here can throw off the entire project.

Then there’s the concrete mix itself, which is a science all its own. This isn’t the same stuff you see on sidewalks. Artisans carefully blend high-performance cements, specific aggregates, and sometimes strengthening additives like glass fibers to create a mix that’s both incredibly strong and capable of a beautiful finish.

Investing in a concrete countertop means investing in the artisan. You’re paying for their experience, their eye for detail, and their ability to troubleshoot the unique challenges that every custom project presents. It’s the difference between a functional surface and a masterpiece.

After the pour, the real work begins. The process involves meticulous troweling to get that smooth, dense surface, followed by a controlled curing period that can take weeks. Curing isn’t just about letting it dry—it’s a critical chemical reaction that gives the concrete its strength. If this step is rushed or the environment isn’t right, you can end up with a weak, cracked, or flawed countertop.

The Breakdown of Installation Costs

When you look at the numbers, it becomes obvious why labor plays such a huge role. The raw materials are surprisingly affordable, but the expertise needed to turn them into a finished countertop is what really shapes the budget.

Labor accounts for a massive 60-70% of the total bill. While the material itself might only be $5-15 per square foot, the hands-on work pushes the fully installed average to $117-168 per sq ft.

This pricing directly reflects all the hands-on stages of the job:

- Mold Creation: Building precise forms for your unique layout, including sink cutouts and decorative edge details.

- Mixing & Pouring: Nailing the perfect consistency and ensuring an even, void-free pour.

- Finishing: The time-consuming work of grinding, polishing, and sealing the surface to get the exact sheen and durability you want.

- Installation: Carefully transporting the heavy, finished slab and expertly setting it in place without a single chip or scratch.

It’s a Different League Than Other Materials

When you compare concrete installation to other materials, you really see the difference. Laminate is cut and glued down. Granite and quartz slabs are pulled from a quarry or factory, cut to size, and then installed by a team. While stone installation definitely requires skill, it’s mostly about fitting a pre-made product into a space.

Concrete is the exact opposite. It’s fabricated from raw ingredients for each individual job. The artisan isn’t just an installer; they’re the manufacturer, finisher, and designer all rolled into one. This is why finding the right professional is so critical. Working with experienced kitchen remodeling contractors near me is crucial for a complex project like this. They already have a network of vetted artisans who can guarantee a flawless result that will look amazing and last for decades.

How Concrete Compares To Other Countertop Materials

Picking a countertop is a lot more than just choosing a color. You’re really selecting a material that has to work with your lifestyle, your budget, and the look you’re trying to achieve. When you’re looking at the concrete kitchen countertops cost, it’s crucial to see how it stacks up against the other big players on the market.

Concrete holds a really interesting position. It’s not a quarried stone like granite, nor is it an engineered slab like quartz. Think of it less as a budget-friendly option and more as a premium, artisanal surface. Its real value isn’t in being the cheapest, but in its incredible adaptability. While granite gives you raw, natural beauty and quartz delivers engineered perfection, concrete is a blank canvas. This is where it really shines for anyone wanting a truly one-of-a-kind kitchen centerpiece.

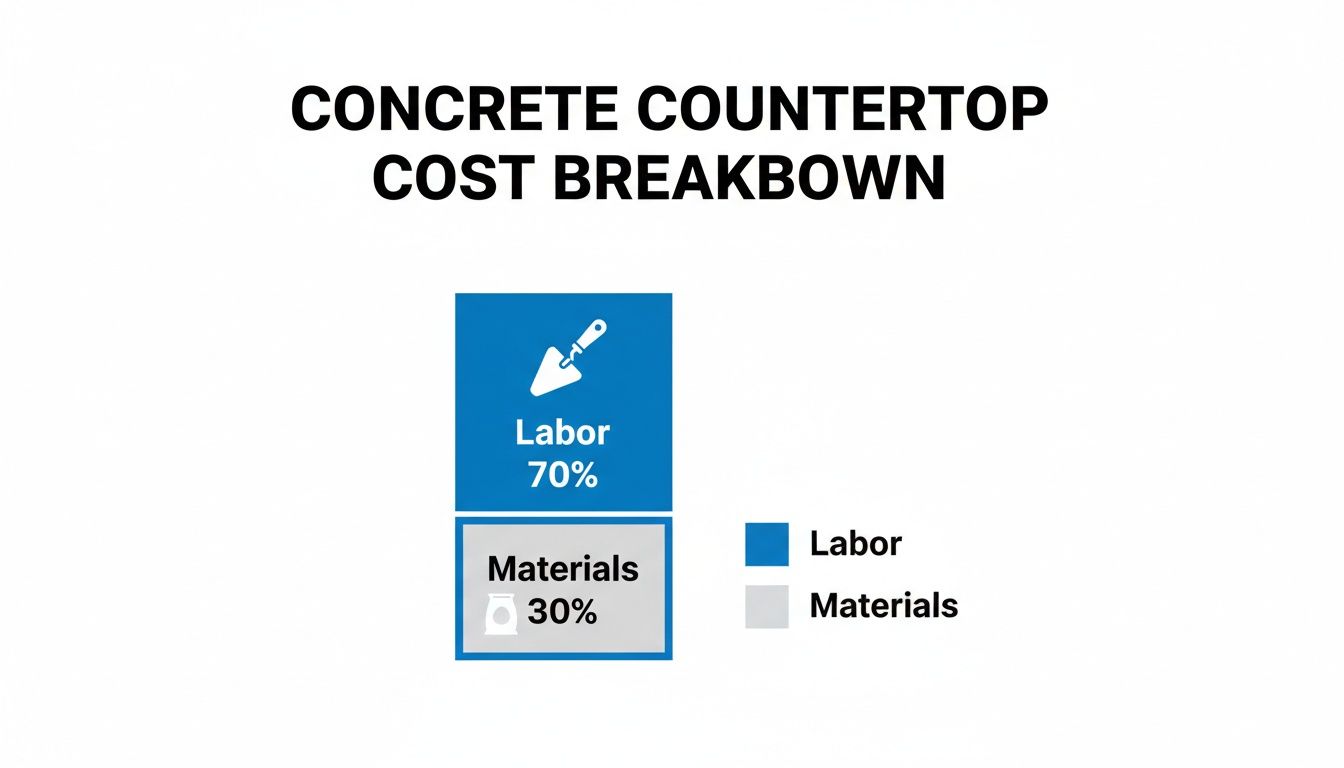

This breakdown shows you where your investment goes—and why the craftsmanship is such a huge piece of the puzzle.

As you can see, the vast majority of the cost—a whopping 70%—is dedicated to the skilled labor needed to craft a flawless, durable work of art in your home.

Concrete Versus Natural Stone

For decades, natural stones like granite and marble have been the go-to for high-end kitchens. Each one has a distinct personality, and knowing their quirks is key to making the right call.

Granite ($60-$100/sq. ft.): Granite is a true workhorse. It’s incredibly durable and stands up to heat like a champ. Every single slab is unique, with natural patterns and flecks of color that can never be perfectly replicated. The catch? You’re limited to what the earth creates, so finding a slab that perfectly fits your vision can sometimes be a hunt. It also needs to be sealed periodically to keep it from staining.

Marble ($100-$200/sq. ft.): Nothing says classic elegance quite like marble. It has a luxurious look and feel that’s hard to beat, and its naturally cool surface is a dream for bakers. The downside is significant, though. Marble is a softer, more porous stone, which means it’s prone to scratching, etching from acidic things like lemon juice, and staining. It demands serious care and is best for homeowners who are ready for that level of upkeep.

Concrete, on the other hand, gives you the toughness of granite with a level of customization that natural stone just can’t touch. It also needs sealing, but you can control everything from the exact shade of grey to the finish, giving you a creative freedom that’s simply not on the table with quarried stone.

Concrete Versus Engineered Surfaces

Engineered materials, especially quartz, have exploded in popularity because they’re so consistent and easy to care for. They offer a completely different set of pros and cons when compared to the artisanal vibe of concrete.

Quartz ($80-$150/sq. ft.): Made from crushed quartz crystals bound together with resin, this stuff is tough. It’s non-porous, resists scratches and stains, and never needs to be sealed. It’s the definition of low-maintenance. Quartz is available in a huge range of colors and patterns, many of which do a great job of mimicking natural stone. The trade-off is that the patterns are engineered and can look a bit repetitive to a discerning eye, lacking the organic character of concrete or granite.

The real difference comes down to character. Quartz offers predictable, uniform perfection. Concrete offers bespoke artistry. Your choice often depends on whether you value a flawless, factory-made surface or a unique, handcrafted piece with its own subtle, one-of-a-kind story.

This is a good starting point, but for a deeper dive into all your options, our guide on how to choose kitchen countertops can help you get even more clarity. Thinking about materials goes beyond just the big surfaces; understanding the properties of everything in your kitchen is key. For example, you might find it helpful to look at a comprehensive guide to cookware materials to see how these concepts apply elsewhere.

Countertop Material Cost And Feature Comparison

To help you see everything in one place, we’ve put together a simple table comparing the leading countertop materials. It breaks down all the key factors, from cost to durability, so you can easily see where concrete fits in.

| Material | Average Cost (Per Sq. Ft. Installed) | Pros | Cons | Best For |

|---|---|---|---|---|

| Concrete | $70 – $150 | Fully customizable (color, shape, finish), heat resistant, durable, unique look. | Requires sealing, can develop fine cracks, artisan-dependent quality. | Creative homeowners who want a one-of-a-kind, personalized kitchen. |

| Granite | $60 – $100 | Highly durable, heat resistant, each slab is unique. | Requires sealing, limited to natural colors, visible seams. | Busy kitchens needing a durable surface with natural beauty. |

| Quartz | $80 – $150 | Extremely durable, non-porous, no sealing needed, consistent patterns. | Less heat resistant than granite, can look uniform, higher cost. | Those who prioritize low maintenance and a clean, consistent aesthetic. |

| Marble | $100 – $200 | Timeless elegance, stays cool for baking, beautiful veining. | Scratches and etches easily, porous and stains, high maintenance. | Luxury kitchens where aesthetic is the top priority over durability. |

In the end, concrete countertops hold a unique position. They feel right at home in both high-end luxury designs and busy family kitchens. With an installed cost of $70 to $150 per square foot, they sit comfortably in the market and offer a level of personalization you just can’t get from other materials. This makes concrete the perfect choice for anyone who values bespoke design and is ready to invest in a surface that is truly their own.

Budgeting For Your Project: Real South Florida Examples

Numbers on a page can feel a bit abstract. The best way to understand the real concrete kitchen countertops cost is to see how it plays out in actual projects. Let’s walk through three different scenarios, all inspired by homes right here in our South Florida community.

Each example highlights how different choices—from size and complexity to the final finish—directly impact the bottom line. Think of these as stories that will help you visualize your own space and get a feel for the investment required to bring your vision to life.

Case Study 1: The Highland Beach Condo Island

Picture a sleek, modern condo overlooking the ocean in Highland Beach. The owner wants to create a true statement piece: a kitchen island that doubles as a work of art. The goal is a dramatic centerpiece with pristine lines and a luxurious finish.

- Scope: A 40-square-foot island countertop.

- Key Feature: A striking waterfall edge on one side, where the concrete seems to pour seamlessly down to the floor. This adds an extra 10 square feet of vertical surface.

- Material: A high-end, polymer-modified precast mix for an incredibly smooth, almost flawless surface.

- Finish: Highly polished light grey with an integral color, sealed with a high-performance, food-safe epoxy for maximum durability and shine.

Here’s how the costs for a high-design project like this typically break down:

| Item | Calculation | Estimated Cost |

|---|---|---|

| Countertop Surface | 50 sq. ft. @ $120/sq. ft. | $6,000 |

| Waterfall Edge Labor | Custom formwork and finishing | $1,200 |

| High-Polish Finish | Extra grinding & polishing steps | $800 |

| Installation | Specialized delivery and install | $900 |

| Project Total | $8,900 |

This project is a perfect example of how a signature feature like a waterfall edge, combined with a premium finish, elevates the final investment.

Case Study 2: The Parkland Family Kitchen

Next, let’s head over to a busy family home in Parkland. They need a large, durable kitchen that can stand up to homework, art projects, and big family dinners. The priority here is function and a warm, inviting feel, rather than high-gloss drama.

- Scope: 60 square feet of perimeter countertops.

- Key Feature: A beautiful, integrated concrete sink that’s completely seamless with the counter.

- Material: A standard precast concrete mix with a charcoal integral pigment for a rich, deep color.

- Finish: A practical, semi-gloss honed finish with a durable acrylic sealer that’s easy to maintain.

- Edge Profile: A simple, eased square edge for a clean and contemporary look.

Let’s look at the budget for this functional, family-friendly space:

| Item | Calculation | Estimated Cost |

|---|---|---|

| Countertop Surface | 60 sq. ft. @ $95/sq. ft. | $5,700 |

| Integrated Sink | Custom mold and finishing | $1,500 |

| Cutouts & Faucet Holes | Standard fabrication | $300 |

| Installation | Standard install for multiple pieces | $1,000 |

| Project Total | $8,500 |

The integrated sink is a significant part of the cost, but it delivers a stunning, one-of-a-kind look that’s also incredibly practical and easy to clean.

Case Study 3: The Delray Beach Galley Kitchen

Finally, imagine a chic but compact galley kitchen in a downtown Delray Beach townhome. The owner’s goal is to pack a lot of style into a small footprint without a huge budget. This project proves that concrete countertops aren’t just for massive kitchens.

- Scope: 25 square feet of countertop space.

- Key Feature: Simple, straight runs with no complex angles or corners.

- Material: Standard precast concrete in its natural, unpigmented grey.

- Finish: A cost-effective matte finish sealed with a quality penetrating sealer.

- Edge Profile: A standard square edge.

Here’s the straightforward cost breakdown for this smart and stylish project:

| Item | Calculation | Estimated Cost |

|---|---|---|

| Countertop Surface | 25 sq. ft. @ $80/sq. ft. | $2,000 |

| Sink Cutout | Standard cutout for a drop-in sink | $150 |

| Installation | Simple delivery and install | $600 |

| Project Total | $2,750 |

As you can see, concrete can be a surprisingly accessible option for smaller projects, especially when the design is kept clean and simple.

Of course, even with its incredible customization, it’s always smart to weigh your options. To see how these numbers stack up against another popular material, take a look at our guide on the cost of quartz countertops to get a complete picture of your premium surface choices.

Smart Ways to Keep Your Concrete Countertop Budget in Check

Just because you’re investing in a custom surface doesn’t mean you have to drain your bank account. With a few smart decisions, you can manage the cost of your concrete kitchen countertops and still get that high-end look you’re after.

It’s less about cutting corners and more about making savvy choices that match your budget and your style. Think of it like buying a car—the base model is great, but every add-on bumps up the price tag. By being intentional with your customizations, you can control the final cost without sacrificing the quality and raw beauty of the concrete.

Focus On High-Impact, Low-Cost Details

Some of the most powerful design choices are surprisingly budget-friendly. By simplifying a few elements, you can free up funds for the features that really make a difference to you.

Here are a few practical strategies to consider:

- Stick with the Standard Thickness: A 1.5-inch thick countertop gives you that classic, substantial concrete look without the extra material and labor costs that come with a thicker slab.

- Keep the Edge Profile Simple: A clean, square edge is modern, timeless, and the most economical choice by far. Fancy edge profiles, like an ogee or a full waterfall, require complex forms and a ton of finishing work, which drives up the price.

- Go with an Integral Color: Adding pigment directly into the concrete mix is far more efficient than applying topical acid stains later on. Stains require more hands-on, artistic labor, making them a more expensive route.

Here’s a little insider tip for managing costs: let the material do the talking. A simple, beautifully crafted design often has more impact than one cluttered with expensive features. Embrace the natural character of the concrete and let it be the star of the show.

Be Strategic About Your Finish and Project Scope

The final finish you choose and how you plan the installation can also offer some real savings. For instance, that highly polished, mirror-like surface is a huge cost driver because it requires hours and hours of multi-stage grinding. Choosing a honed or matte finish gives you a gorgeous, soft aesthetic for a fraction of the labor cost.

Also, think about the bigger picture. If your countertops are part of a larger kitchen remodel, bundling the installation with the rest of the work can often lead to savings. Your general contractor can schedule trades more efficiently, which might reduce overall labor costs and make the whole project run smoother. A little bit of planning upfront can make your dream concrete countertop a very affordable reality.

Your Top Concrete Countertop Questions, Answered

As you get closer to making a decision, you probably have a few practical questions bubbling up about what it’s really like to live with concrete countertops. It’s smart to think about the long game. Let’s tackle the most common things people ask so you can feel confident about your investment.

What Kind of Upkeep Are We Talking About?

Good news: long-term maintenance is pretty minimal, but consistency is key. Your countertop’s number one defense against stains and moisture is its sealer, and your main job is just to keep that protective layer in good shape.

For most kitchens, we suggest resealing the countertops every one to three years. The timeline really just depends on how heavily you use the surface. It’s a simple process that keeps your countertops looking brand new. For daily cleaning, all you need is a soft cloth and a gentle, non-abrasive soap—steer clear of anything harsh or acidic, like vinegar, which can eat away at the sealer.

Will They Stain or Crack Easily?

This is probably the biggest concern we hear, and it’s a fair question. People immediately picture a cracked sidewalk, but countertop concrete is a whole different world.

- Staining: When it’s properly sealed, concrete is incredibly stain-resistant. The sealer creates an invisible barrier. As long as you wipe up spills reasonably quickly, you won’t have any issues. The only time staining becomes a risk is if the sealer has worn thin or if something acidic, like red wine or lemon juice, is left to sit for a very long time.

- Cracking: The concrete mixes we use today are nothing like the stuff on the street; they’re packed with reinforcements like fibers to handle the tension of a busy kitchen. That said, it’s possible for tiny, non-structural hairline cracks to appear over time as the house settles. Honestly, many people love this aspect—they feel these subtle fissures add to the raw, living character of the material.

How Long Does the Whole Process Take?

Creating a custom concrete countertop is true craftsmanship, and that takes time. You’ll need a little patience here. From the day we make the templates in your kitchen to the final installation, you can expect the project to take about four to six weeks.

Why so long? This timeline is crucial for getting it right. It includes building the molds to your exact specifications, giving the concrete plenty of time to cure (this is where it gets its strength!), and the detailed work of grinding, polishing, and sealing. Rushing any step just isn’t an option if you want a beautiful, durable result.

Will They Help My Home’s Resale Value in South Florida?

In a hot market like Boca Raton or Delray Beach, anything that makes a home feel custom and high-end is a huge plus. A beautifully executed concrete countertop does exactly that. It tells potential buyers that this isn’t a cookie-cutter kitchen.

While granite or quartz might be more familiar to the average person, for a buyer with an eye for design, a concrete countertop can be the very thing that makes them fall in love with the house. It’s a “wow” factor that adds a unique, bespoke feel, helping your home stand out and positively impacting its overall appeal and value.

Ready to see what a custom concrete countertop could look like in your kitchen? The design experts at Kitchen Renovations Perfected are here to help. Visit our Boca Raton showroom or schedule your free consultation today!