When you start looking at new countertops, one of the first questions is always about the price. For concrete countertops, you can expect the cost to land somewhere between $65 to $140 per square foot, including installation. The final number really depends on how intricate your design gets—think of it less like buying a slab and more like commissioning a custom piece of furniture.

Decoding Concrete Countertop Prices

It’s important to understand what goes into that price tag. Unlike granite or quartz slabs that are pulled from a warehouse, every single concrete countertop is made from scratch for a specific project. This artisan process means you’re paying for much more than just cement and sand; you’re investing in design, technical skill, and a completely personalized finish.

This price range puts concrete right in the mix with other high-end materials. It’s often more affordable than premium quartz, which can easily top $100+ per square foot, but it’s a definite step up from budget-friendly laminates that run $20-$50 per square foot.

How Concrete Compares to Other Materials

To really get a feel for the value, it helps to see how concrete stacks up against other popular choices. Each material has its own sweet spot when it comes to cost, durability, and style. Where concrete truly shines is its incredible flexibility for customization.

Here’s a quick look at how the numbers break down for some of the most common countertop options.

Cost Comparison: Concrete Vs. Other Materials

This table gives you a snapshot of average installed costs per square foot for popular countertop options, helping you quickly benchmark where concrete fits into your budget.

| Material | Average Installed Price Per Sq. Ft. | Best For |

|---|---|---|

| Concrete | $65 – $140 | Custom shapes, unique colors, and integrated sinks |

| Granite | $60 – $100 | Natural stone patterns and heat resistance |

| Quartz | $80 – $150+ | Uniform appearance and zero-maintenance durability |

| Laminate | $20 – $50 | Budget-friendly projects and a wide variety of looks |

| Marble | $100 – $200 | Luxury aesthetics and classic, timeless appeal |

As you can see, while concrete is considered a premium material, its cost is directly tied to the craftsmanship and unique design possibilities you just can’t get with other surfaces.

The Artistry Behind the Price Tag

At the end of the day, the price of a concrete countertop is a direct reflection of the skilled labor and detailed work involved. It’s a concept that applies to many custom home features, and understanding the truth behind hardscape pricing can clear up a lot of misconceptions about what you’re truly paying for.

From building the initial mold to the final grind and polish, every step requires precision. The price accounts for the artisan’s time to create perfect templates, mix pigments for your ideal shade, and apply high-performance sealers that protect your investment for years to come.

Breaking Down What Drives the Cost

When you get a quote for a concrete countertop, you’re not just paying for a slab of material. You’re paying for craftsmanship, artistry, and a whole lot of science. The final price tag is a sum of its parts—the specific ingredients, the structural engineering, and the complexity of the design you’ve dreamed up. Knowing what these parts are helps you understand where your money is going and how to balance your vision with your budget.

Think of it like commissioning a custom piece of furniture. A simple pine table is one thing; a handcrafted walnut dining table with intricate inlays is something else entirely. The same logic applies here, starting with the very mix that forms your countertop.

The Foundation: Your Concrete Mix

The recipe for the concrete is the first big fork in the road, and it has a major impact on cost. While every mix starts with the basics—cement, sand, and water—the advanced formulas we use today are engineered for performance and aesthetics.

- Standard Cement Mix: This is your classic, most budget-friendly option. It’s perfectly suitable for many indoor projects, but it absolutely depends on a solid reinforcement plan and a high-quality sealer to stand the test of time.

- Glass-Fiber Reinforced Concrete (GFRC): This stuff is a game-changer. By mixing in tiny glass fibers, we can create a countertop that is incredibly strong yet surprisingly lightweight and flexible compared to traditional concrete. GFRC is what allows us to design those dramatic, long islands with minimal support and other complex shapes, making it a very popular—though pricier—choice.

- Polymer-Modified Mix: This is the high-end of the spectrum. Adding specialized polymers to the mix creates an incredibly dense and non-porous surface. The result is a countertop with a silky-smooth finish and superior stain resistance right out of the mold. As you might guess, this premium performance comes with the highest material cost.

The mix you choose sets the stage for everything, affecting both material costs and the labor required. For a deeper look into material choices, our guide on the cost of concrete countertops offers more detailed comparisons.

The Backbone: Reinforcement Choices

Just like a skyscraper needs a steel skeleton, a concrete countertop needs internal reinforcement. This isn’t an optional add-on; it’s what guarantees the countertop won’t crack under the stress of daily life. The type and complexity of this internal structure will definitely influence the final cost.

For a traditional, thick-poured countertop, this usually means a carefully placed grid of steel rebar or wire mesh inside the form. With the lighter GFRC, the glass fibers provide reinforcement throughout the mix, but we often add strategic structural support for tricky areas like large sink cutouts or long, unsupported overhangs.

The amount of reinforcement isn’t a guess—it’s an engineering calculation. Things like sink openings, cooktop cutouts, and cantilevered bar tops all create stress points that demand extra support. That extra engineering and material adds to the labor and cost.

The Blueprint: Formwork Complexity

If there’s one factor that can really move the needle on price, it’s the formwork. This is the custom-built mold that gives the concrete its final shape, size, and details. The form is literally the blueprint for your countertop.

A simple rectangular slab with straight edges requires a pretty basic form, making it the most cost-effective design. But the real magic of concrete is its ability to be molded into almost anything you can imagine, and that level of customization is where the cost reflects the skill involved.

- Curves and Unique Shapes: Want a big, sweeping curve on your kitchen island? Or a top that fits perfectly into a quirky, non-square corner? Those organic shapes require a fabricator to build a meticulously crafted, custom mold, which is a significant investment of time and expertise.

- Integrated Features: This is where concrete really shines. We can build the sink right into the countertop for a seamless look or create a custom-sloped drainboard next to it. These features are stunning, but they make building the formwork exponentially more complex.

- Cutouts and Inserts: Every single hole—for a sink, a faucet, a soap dispenser, or a cooktop—adds to the job. Each one has to be perfectly placed and reinforced within the mold to ensure the final product has crisp, clean edges and structural integrity.

At the end of the day, the formwork is where your vision starts to become a reality. The more ambitious the design, the more complex and costly the mold will be.

How Custom Features Shape Your Final Price

The real magic of concrete is that you can make it into almost anything you can imagine. While the concrete mix and internal reinforcement set the baseline for your cost, it’s the artistic details and custom features that truly bring your vision to life. This is also where the budget can see its biggest swings.

Think of it like buying a car. The base model will get you from point A to B, no problem. But it’s the leather seats, the premium sound system, and the sunroof that completely change the driving experience. Every upgrade adds value and, of course, cost. The same is true for concrete countertops; every design choice, from the surface finish to the edge profile, plays a part in the final number.

The Impact of Surface Finishes

The finish is what gives your countertop its final look and feel, and the labor involved can vary wildly. A simple, hand-troweled finish is a world away from the multi-stage process required for a glass-like polish.

- Troweled Finish: This is your most straightforward and budget-friendly choice. As the concrete sets, the surface is smoothed by hand with a trowel, which creates a beautiful, slightly organic texture. It’s perfect for a rustic or industrial vibe without a ton of extra labor.

- Lightly Honed/Sanded Finish: Taking it a step further, we can lightly grind the surface to buff out any trowel marks. The result is a smooth, matte appearance that feels refined without being glossy. It’s a very popular middle-of-the-road option.

- Heavily Polished/Ground Finish: This is where the real artistry comes in. To get that deep, reflective sheen, a fabricator grinds the surface with progressively finer diamond pads. This process not only polishes the surface but also exposes the sand and aggregate inside the mix, creating a stunning terrazzo-like effect. It’s the most labor-intensive finish, and the price reflects that.

Digging into residential polished concrete options can give you a better sense of how different looks tie back to the work involved and the overall cost.

Choosing Your Edge Profile

Don’t underestimate the power of the edge—it’s the detail that frames the entire countertop. A simple, squared-off edge is standard, but more complex profiles demand intricate formwork and careful hand-finishing, which naturally adds to the cost.

| Edge Style | Description | Cost Impact |

|---|---|---|

| Square/Eased | A clean, minimalist look with slightly softened corners to prevent chipping. | Low |

| Bullnose | A fully rounded edge that gives off a classic, soft appearance. | Moderate |

| Beveled | An angled or chamfered edge that adds a subtle, geometric detail. | Moderate |

| Waterfall | A dramatic statement where the countertop turns 90 degrees and runs vertically down the side of the cabinet to the floor. | High |

| Custom Ogee | An intricate, S-shaped curve that creates a highly decorative, traditional look. | High |

The waterfall edge, in particular, is a showstopper. It uses a lot more material and labor but creates an incredible, monolithic focal point in a modern kitchen.

The Ultimate Customization: Integrated Features

This is where concrete truly pulls away from the pack. Because it starts as a liquid, we can cast features like sinks and drainboards directly into the countertop. You get a one-of-a-kind functional sculpture. These integrations take immense skill and directly influence the final price.

An integrated sink is probably the most requested custom feature we do. We build the sink mold right into the countertop form, creating a seamless basin with no grout lines. It’s not only gorgeous but also incredibly easy to clean. This feature alone can add $1,000 to $2,500+ to a project.

Other popular built-in features include:

- Drainboards: We can cast sloped grooves right next to the sink, so water drains directly into the basin.

- Trivets: Stainless steel bars or other heat-resistant elements can be embedded near a cooktop, giving you a built-in spot for hot pots.

- Inlays: We can embed just about anything—recycled glass, beautiful stones, even fiber optics—for a look that’s 100% yours.

This level of personalization is a huge advantage. For instance, in a competitive market like Boca Raton, Florida, expert fabricators can use concrete’s moldability to create custom edges and sinks, which can reduce fabrication waste by 25% compared to cutting similar features from a massive stone slab.

Ultimately, every custom touch adds layers of complexity, from building the initial mold to the painstaking finishing work. To see how all this compares to other surfaces, check out our kitchen countertop materials comparison.

The Craftsman’s Touch: Breaking Down Labor and Installation Costs

So, we’ve talked about materials, finishes, and all the cool custom features that make up your concrete countertop. But what pulls it all together? The artisan. The labor cost isn’t just about hauling a heavy slab into your kitchen; it’s the price of skill, artistry, and a whole lot of meticulous work that happens behind the scenes.

This is one part of the project you absolutely don’t want to skimp on. I’ve seen enough DIY attempts to know that the specialized tools and, more importantly, the experience required are well beyond most weekend warrior projects. Think of your fabricator as both a sculptor and an engineer—they’re the ones who turn a pile of raw materials into a functional piece of art that fits your space to the millimeter. The labor cost covers this entire journey, ensuring your new countertop is beautiful the day it’s installed and tough enough to last for decades.

From Template to Masterpiece: The Fabrication Process

The real work starts long before a single drop of concrete is mixed. It all begins in your home but quickly moves to a dedicated workshop where the magic happens. This off-site fabrication, or precasting, is how most high-end countertops are made. It keeps the mess out of your house and gives the artisan the controlled environment they need to get every detail perfect.

Here’s a quick look at what that process involves:

- Making the Perfect Pattern: First, the artisan visits your home to create a precise template. This isn’t a rough sketch—it’s an exact pattern that maps every corner, curve, and cutout for your sink and cooktop.

- Building the Mold: Back in the shop, that template becomes the blueprint for a custom mold, or “form.” The quality of the form is non-negotiable. Any tiny flaw here will be permanently cast into your countertop.

- The Pour and the Patient Wait: The concrete mix is prepared with exact ratios and poured into the form. Then comes the curing—a critical waiting period that can take days or even weeks. This slow, controlled process is essential for the concrete to gain its full strength and avoid future cracks.

The Final Stretch: Finishing and Setting in Place

Once the slab has fully cured and is popped from its mold, it’s still just a raw piece of concrete. The finishing stage is what transforms it into the smooth, polished surface you envisioned. Naturally, the more complex the finish, the more time and effort it takes.

The last big steps covered by the labor quote are:

- Grinding it Out: Using a sequence of diamond-grit pads, the artisan grinds and polishes the surface. They move from coarse grits to incredibly fine ones to achieve everything from a soft, matte feel to a glossy, reflective shine.

- Sealing the Deal: Next, a high-performance, food-safe sealer is carefully applied in several layers. This is arguably one of the most important steps, as it’s what gives your countertop its resistance to stains, acids, and moisture.

- The Big Move: Getting a massive, heavy slab of concrete from the workshop to your kitchen is a serious logistical challenge. A professional crew uses specialized equipment to transport it safely and set it perfectly level on your cabinets.

Just how heavy are we talking? A standard 2-inch thick concrete countertop weighs about 25 pounds per square foot. For a typical kitchen island, that can easily top 500 pounds. This is why professional installation isn’t just a good idea—it’s a must for safety and the structural integrity of your home.

When you see that final invoice, remember that the labor cost reflects a huge amount of skill, precision, and pure physical effort. You’re not just paying for a product; you’re investing in craftsmanship that guarantees a beautiful, safe, and perfectly installed centerpiece for your home.

Budgeting for Your Concrete Countertop Project

Knowing the price per square foot is a good starting point, but it doesn’t tell the whole story. To really get a handle on your budget, you need to see how those numbers play out in the real world. A concrete countertop’s final price tag is a blend of its size, the design choices you make, any custom features you add, and the expert labor required to bring it all to life.

Let’s walk through a few common project scenarios to give you a tangible feel for how the scope and features can move the needle on cost. From a simple bathroom vanity to a show-stopping outdoor kitchen, you’ll see exactly where your investment goes.

Three Common Project Scenarios

Here’s a breakdown of what you might expect to pay for a few typical projects, showing how the price scales with size and complexity.

- Scenario 1: The Small Bathroom Vanity (20 sq. ft.)

A simple, precast concrete top is a fantastic choice for a small guest bath or powder room. This budget assumes a standard thickness, a clean square edge, and a single cutout for an undermount sink. The finish is a simple, lightly honed matte look—understated and elegant.- Estimated Cost: $2,000 – $3,500

- Scenario 2: The Standard Family Kitchen (55 sq. ft.)

This covers a typical L-shaped kitchen with a decent-sized island. Here, we’re stepping it up with a more advanced GFRC mix for the island to support an overhang. The project includes a large cutout for a farmhouse sink and another for a cooktop. The finish is a lightly polished surface that lets just a bit of the fine aggregate show through.- Estimated Cost: $6,000 – $9,500

- Scenario 3: The High-End Outdoor Kitchen (70 sq. ft.)

Now we’re pulling out all the stops. This is a large, U-shaped layout with thick, beefy countertops built to last. It features a dramatic waterfall edge on one end, a fully integrated sink basin formed from the concrete itself, and cutouts for a grill and a side burner. The concrete is stained a custom color and sealed with a heavy-duty, outdoor-rated sealer for maximum protection against the elements.- Estimated Cost: $11,000 – $18,000+

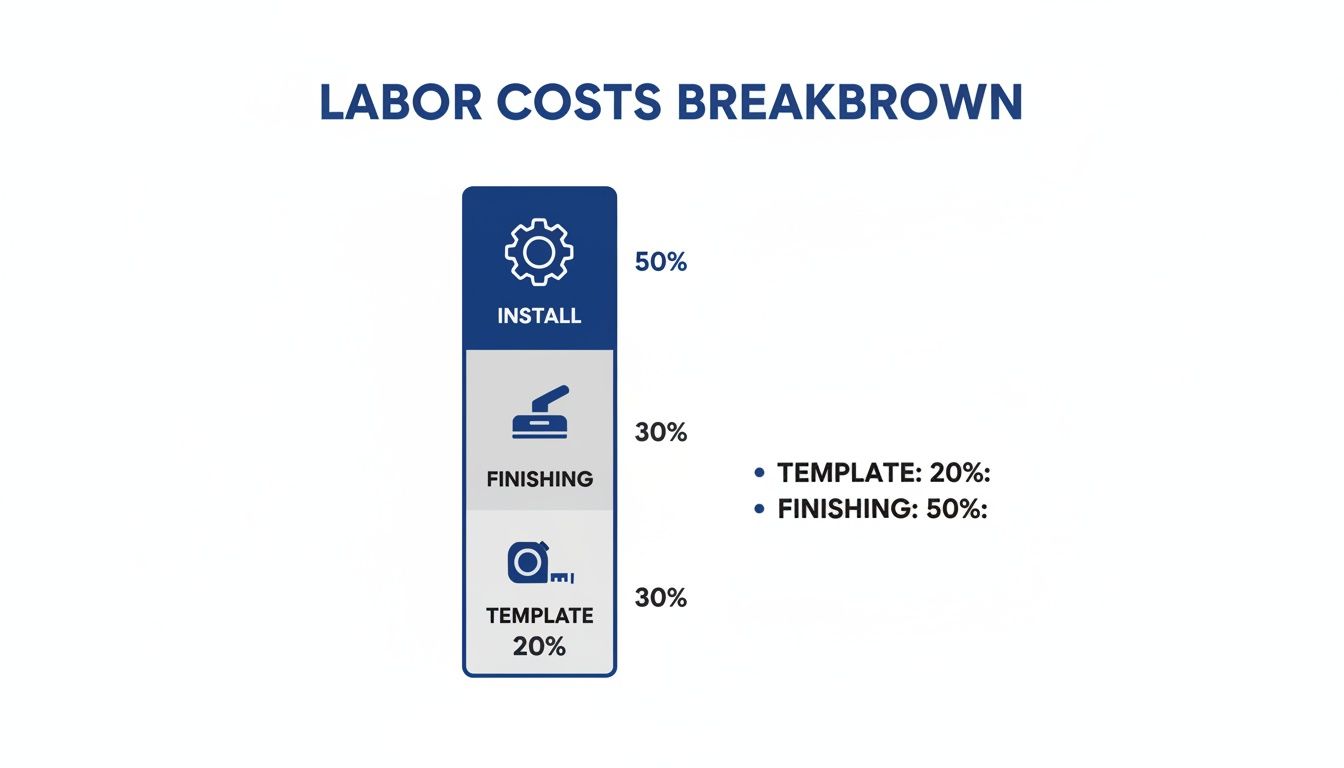

A huge chunk of these budgets is dedicated to the skilled labor involved. This chart shows how those hours are typically spent across the key stages of the process.

As you can see, the hands-on finishing and the final installation account for the lion’s share of the labor. This isn’t just about pouring concrete; it’s about the meticulous craftsmanship that delivers a flawless result.

How to Manage Your Project Costs

Seeing some of those higher numbers might feel a bit daunting, but don’t worry. There are plenty of practical ways to get the beautiful look of concrete without blowing your budget.

The key is to be strategic about where you invest in complexity. Focus your budget on one “wow” feature, like a waterfall island, and keep the surrounding countertops simpler to balance the total cost.

Here are a few tips to help keep your concrete countertop prices in check:

- Keep Shapes Simple: The more straight lines and right angles, the better. Complex curves demand intricate, single-use molds that drive up labor costs significantly.

- Choose Standard Edges: A simple square or eased edge is timeless and the most budget-friendly option. Decorative profiles like an ogee or bullnose require extra finishing work and will add to the bill.

- Limit Custom Features: An integrated sink is a stunning centerpiece, but it’s a major cost driver. Opting for a standard undermount or drop-in sink can easily save you $1,000 or more.

- Select a Simpler Finish: A hand-troweled or lightly honed finish is far less labor-intensive (and thus more affordable) than a highly polished surface that exposes all the aggregate.

Local market conditions also play a big role. For example, recent data from South Florida shows that for Kitchen Renovations Perfected’s clients in Delray Beach, a 50 sq. ft. bathroom vanity costs between $5,500-$8,000 installed when incorporating durable porcelain edges. Meanwhile, for families in Parkland, concrete’s scalability can trim project timelines by 20%, contributing to efficient $15,000 full-kitchen remodels. You can dig deeper into countertop market trends to learn more about how regional factors influence pricing.

The Long-Term Value of Concrete Countertops

It’s easy to get sticker shock when you first see a quote for concrete countertops and only focus on that initial number. But to really understand the cost, you have to look at the bigger picture. A professionally crafted concrete countertop isn’t just a purchase; it’s a genuine investment in your home’s future, adding a unique style and durability that pays off for decades.

Think of it this way: you could buy a cheaper floor that looks good for a few years but needs replacing every decade. Or, you could invest more upfront in something that lasts the life of your home. Concrete is absolutely in that second category. It’s built to last, often outliving trendier materials that can’t handle the wear and tear of daily life.

Durability That Lasts a Lifetime

The biggest selling point for modern concrete countertops is their incredible resilience. We’re not talking about sidewalk concrete here. Advanced mixes and reinforcement techniques have turned these surfaces into workhorses engineered to handle the chaos of a busy kitchen. With a quality installation and basic care, a concrete countertop can easily last 30 years or more, putting it right up there with natural stone like granite.

This strength comes from its high compressive strength, making it incredibly tough to chip or crack under normal kitchen use. While other materials might start showing their age after a few years, a well-made concrete surface keeps its structural integrity and good looks for the long haul.

It’s a common myth that concrete just cracks. Sure, early versions had some issues, but today’s high-performance mixes, often reinforced with glass fibers (GFRC), are engineered to have more flexibility and strength. This drastically reduces the risk of cracking from everyday household activities.

Straightforward Maintenance and Lifecycle Costs

Keeping a concrete countertop looking great is much simpler than most people think. The secret is the sealer, which works like a shield to protect the surface from stains and moisture.

- Daily Cleaning: All you need is a pH-neutral cleaner and a soft cloth. Forget the harsh chemicals or abrasive scrubbers—they’re not necessary and can wear down the sealer.

- Preventative Care: While the surface is very heat-resistant, it’s still smart to use trivets for hot pots and pans. And always use a cutting board to protect both the sealer and your knives.

- Periodic Resealing: The most important long-term maintenance task is resealing, which you’ll typically need to do every 2-5 years. The timing really depends on how much you use your kitchen and the type of sealer applied. It’s a simple job that brings the surface right back to its original, fully protected state.

Because the maintenance is so minimal and the material is so durable, the lifecycle costs are incredibly low. You won’t be staring down the barrel of a full replacement in ten years, which is often the case with materials like laminate. For more insight into their performance, you can explore the detailed pros and cons of concrete countertops. This helps you look past the initial price tag to see the lasting value and minimal upkeep they offer.

This combination of resilience and easy care makes concrete a savvy investment for any homeowner.

Answering Your Top Questions About Concrete Countertop Costs

It’s completely normal to have a lot of questions when you’re looking into custom countertops, especially around pricing and durability. When homeowners start digging into the cost of concrete countertops, a few key concerns almost always pop up. Let’s tackle those head-on so you can get a clear picture.

My goal here is to answer the most common questions about how concrete stacks up against other materials, how it holds up over time, and why professional installation is so crucial. Getting these answers upfront means you can plan your project with confidence, knowing exactly what to expect from your investment.

Are Concrete Countertops Cheaper Than Granite or Quartz?

This is probably the number one question I get. The short answer is: it depends, but generally, no. Concrete countertop prices are very competitive with mid-to-high-end granite and quartz, typically running between $65 to $140 per square foot fully installed.

While you might find a basic, entry-level granite slab for less, custom concrete offers a world of design flexibility that often comes in at a similar price point to premium quartz. Ultimately, the final price tag is all about the complexity of your design and the finish you choose.

Key Takeaway: Think of concrete not as a budget material, but as a premium, artisan one. Its real value is in the incredible customization you can get—things like seamlessly integrated sinks, unique shapes, and embedded personal items—features that are either wildly expensive or simply not possible with natural stone.

Do Concrete Countertops Crack or Stain Easily?

This is a persistent myth, usually based on how concrete used to be made decades ago. Today’s concrete countertops are a completely different animal. They’re crafted from advanced, high-strength mixes and reinforced internally to prevent cracking from normal, everyday kitchen life.

And when it comes to stains? A professionally applied, high-quality, food-safe sealer makes all the difference. This protective layer makes the surface highly resistant to common culprits like red wine, coffee, and oil. Simple, routine maintenance, like resealing every few years, will keep them looking beautiful for a lifetime.

How Much Does Installation Add to the Final Price?

Professional installation isn’t just an add-on; it’s a huge part of what you’re paying for. This is a craft, not just a delivery. The installation cost reflects the expert labor involved in a multi-stage, hands-on process.

Here’s a quick look at what that involves:

- Templating: Creating a perfect, precise template of your cabinets.

- Form Building: Constructing custom molds to your exact design specs.

- Finishing: The meticulous process of pouring, curing, grinding, and polishing the slab to get that perfect finish.

- Sealing: Applying a professional-grade sealer to give it that durable, long-lasting protection.

It stands to reason that a more complex project, say with tricky access to your kitchen or a bunch of cutouts for faucets and cooktops, will require more labor and nudge the final cost up.

Ready to see how a custom concrete countertop could transform your space? The design team at Kitchen Renovations Perfected is here to help. Visit our showroom for a complimentary consultation and get a practical estimate for your project.